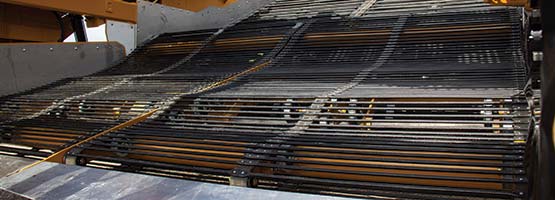

48-INCH-WIDE BELT PATHS

To hold the volume of up to 16 rows of potatoes, all of the flow paths in the harvester need to be wider and deeper. Widening the rear cross, side elevator, and boom by 12 percent makes the extra room necessary to pick up more rows at once.

70-INCH-WIDE CLEANING TABLE

How advantageous would it be to have your handling line cleaning solution built into your harvester? The cleaning table on the 7340 is the full width and nearly the full length of Double L’s flagship dirt eliminator cleaning table. With its cleaning capability, more foreign material will be left in the field than with any other cleaning solution.

ELONGATED DIGGER BED

The longer the primary and secondary chains are, the more product can be dispersed throughout those sections of the harvester. The more spread out the product can be increases the harvester’s ability to sift out dirt from the product flow.

ROBUST FRAME

All of these extra features require a stronger frame to support it all. Double L is renowned for building the beefiest, most durable equipment on the market. Now made with Grade 50 high-strength, low-alloy steel, Double L can add structural strength without adding extra weight to the machine.