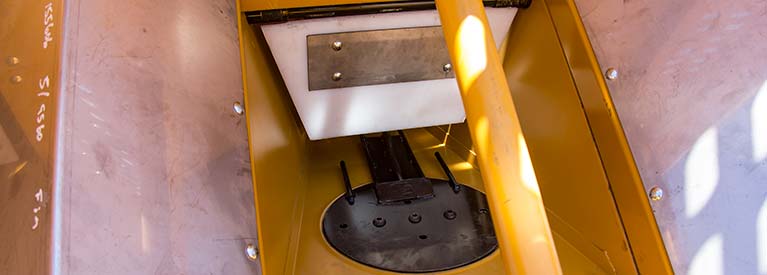

LOW MAINTENANCE DESIGN

The hopper bowl is designed with nearly no moving parts. Few parts translates into low service costs and less downtime for part failures. As long as gravity works, so will the hopper bowl.

HIGH-CAPACITY BOWL

The enormous hopper on Double L's planter line can make quicker work of a huge task. It minimizes how frequently the planter has to stop to be refilled. Fill the hopper and plant for acres without worry.

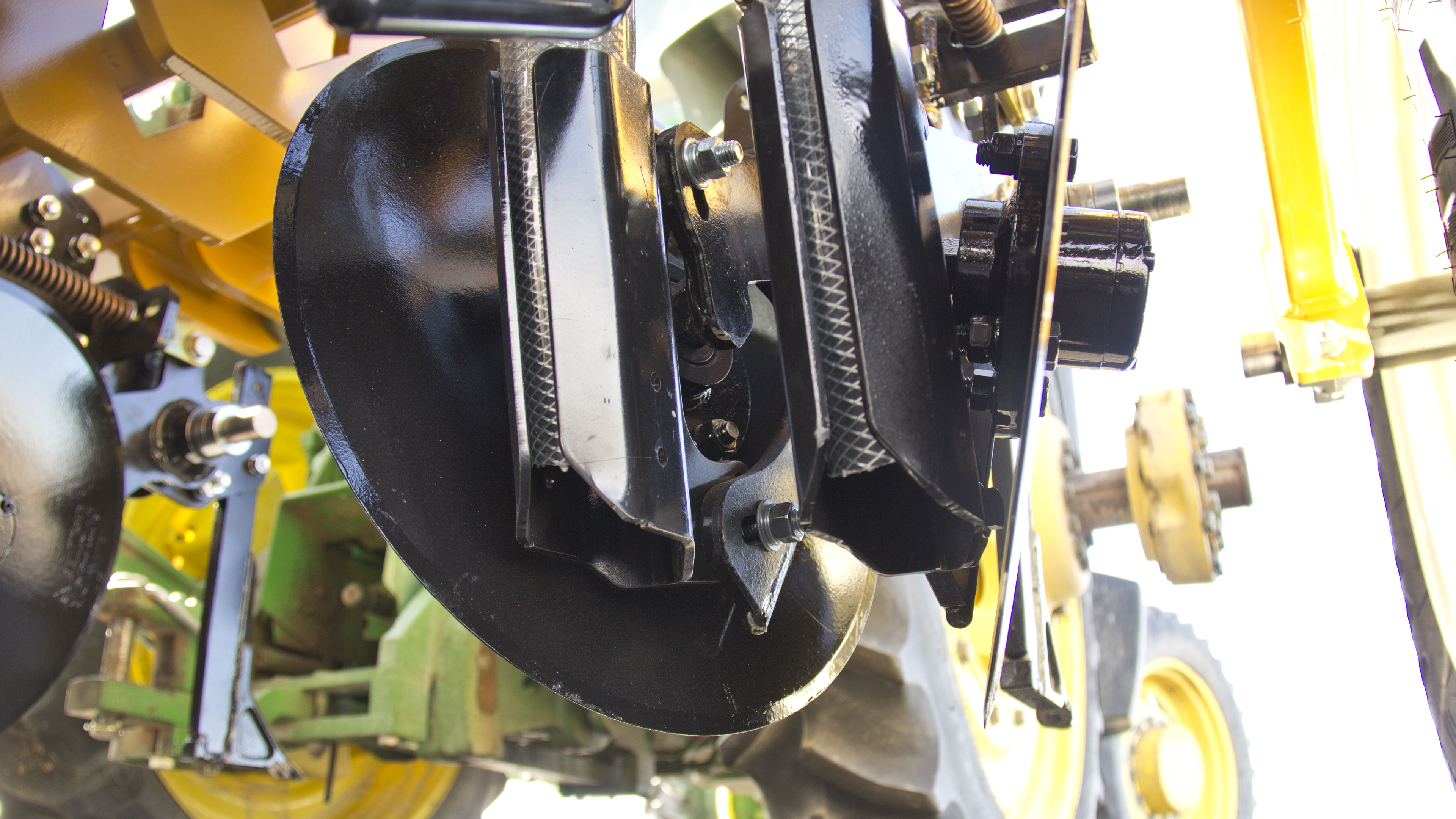

SEED FLOW COMPONENTS

Seed bridging is a concern of farmers for gravity-fed hopper bowls. Double L mitigates blockages with stainless steel gables flanking each planter leg. Their shape removes any flat surfaces on which seed pieces may get caught. Situated above the leg is a round bar support that acts much like a turkey roost inside an even flow tub. It bears some of the weight of the seed and helps it to flow more freely into the planter leg.

SUPER AXLE

The Super Axle is the first of its kind to support the weight of a fully loaded planter on only two tires. A two-tire axle design solves the problem of tire scraping around turns. The machine can turn sharper, and tires and hubs and last longer. It also opens the possibility for towing tillage equipment behind the planter.